I. What is OBD?

OBD is the abbreviation of On-Board Diagnostics, which translates to "On-board Automatic diagnostic system" in Chinese. The system will monitor the engine's operating condition to see if the vehicle is exceeding the emission limit, and if so, it will immediately issue a warning. When the system fails, the fault (MIL) light or Check Engine warning light, while the powertrain control module (PCM) the fault information into the memory, through a certain program can be read from the PCM fault code. According to the fault code prompts, maintenance personnel can quickly and accurately determine the nature and location of the fault.

II.OBD function and its meaning

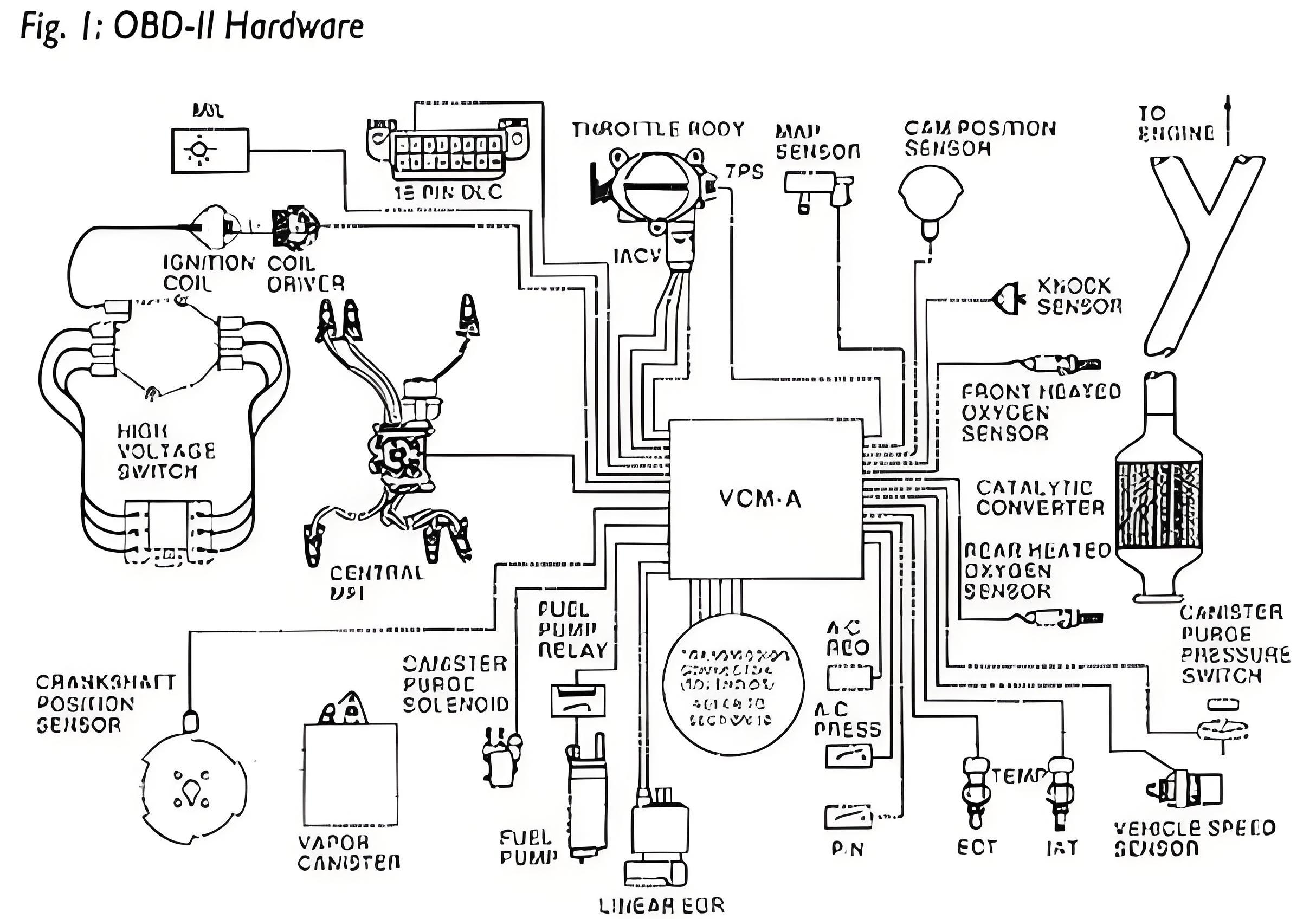

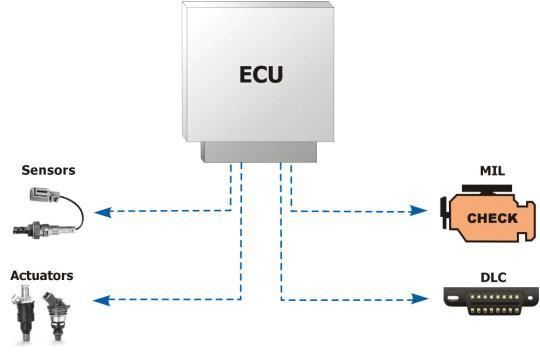

OBD stands for "On-Board Diagnostics". It is a computer-based system originally designed to reduce emissions by monitoring the performance of major engine components. The basic OBD system consists of an ECU (electronic control unit) that uses inputs from various sensors (e.g., oxygen sensors) to control actuators (e.g., fuel injectors) to obtain the desired performance. A "check engine" light, also known as an MIL (fault indicator), provides an early warning of a fault to the owner. Today's vehicles can support hundreds of parameters, which can be accessed via DLC (diagnostic connector) using devices called scanning tools.

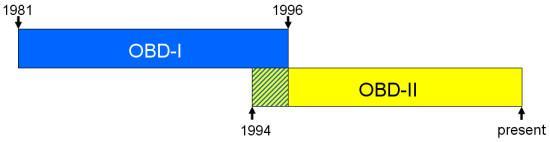

There are two types of on-board diagnostic systems: OBD-I and OBD-II. Obd-iobd-i refers to the first generation of OBD systems developed throughout the 1980s. These early systems used proprietary connectors, hardware interfaces, and protocols. To access diagnostic information, you usually had to buy the right tool for each different vehicle manufacturer. OBD-I scanning tools that support multiple protocols use different adapters. OBD-II In the early 1990s, the Society of Automotive Engineers (SAE) and the International Organization for Standardization (ISO) published a set of standards describing the exchange of digital information between ECUs and diagnostic scanning tools. All OBD-II compliant vehicles must use a standard diagnostic connector (SAE J1962) and communicate via one of the standard OBD-II communication protocols. OBD-II was first introduced in model year 1994 (MY) vehicles, and has been a requirement for all cars and light trucks since model year 1996.

III. Solutions

The vehicle insulation test system produced by Ruijie intelligent, integrates equipotential tester, insulation withstand voltage tester, program-controlled resistance box, multimeter and other equipment, establishes communication with the vehicle through OBD interface, and can carry out AC/DC charging port gun base insulation test, vehicle insulation test, insulation monitoring function verification, capacitive coupling test and ground resistance test.

After the test gun wire harness is connected, the scan code starts the test. After the test is completed, the test data can be automatically saved to form a test report, and the test data can also be automatically uploaded through the MES interface.

National standard "GB 18384-2020"

Factory Address: No.38 Longfei Road, Chengyang District, Qingdao, China